Navigating the Regulatory Seas: How Experts Ensure Your Medical Devices Set Sail Smoothly

Introduction In the ever-changing world of medical device manufacturing, ensuring your product complies with regulations is akin to navigating stormy seas. The safety of patients, the assurance of quality, and the complexities of compliance weigh heavily on manufacturers. This article sheds light on the challenges faced and how expert navigators—regulatory consultants—play a pivotal role in

... Read moreA Clear Guide to FDA 510(k) Submission Requirements

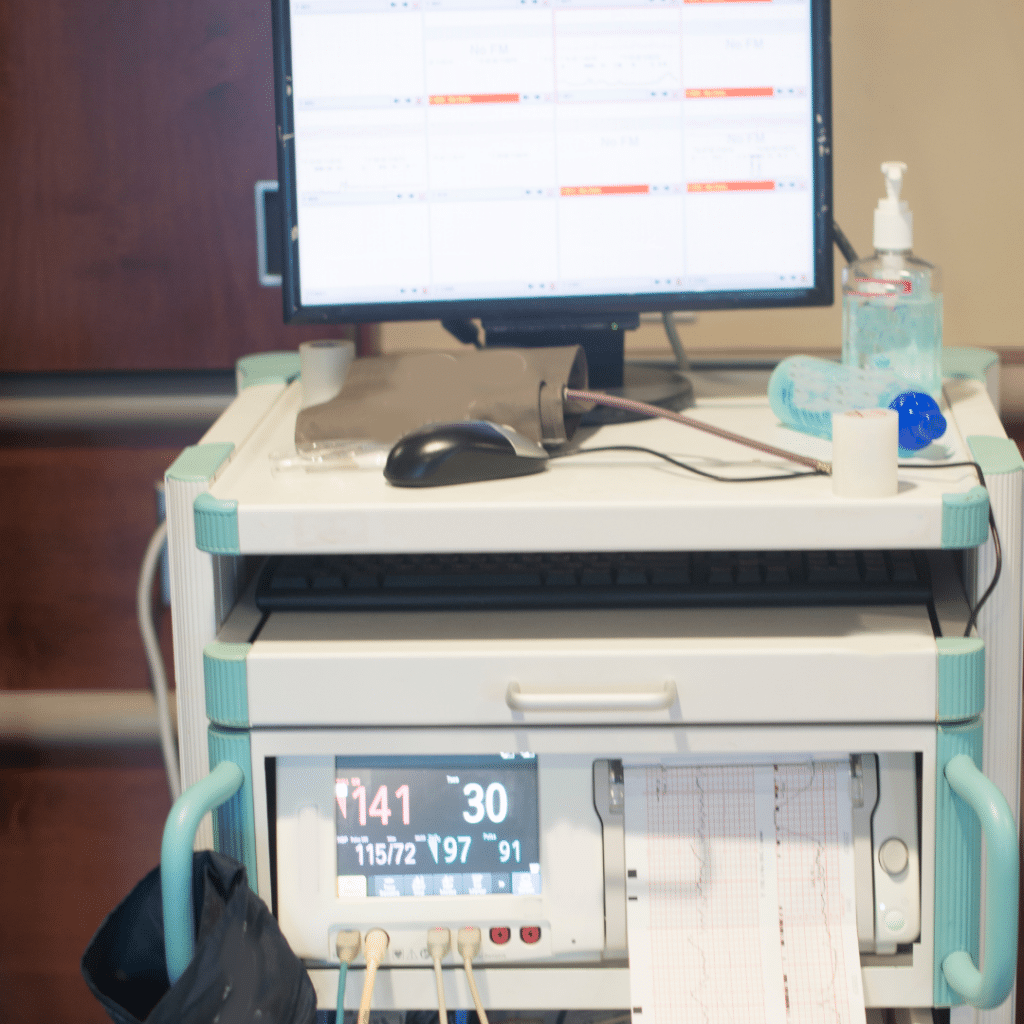

Introduction In the world of medical devices, ensuring patient safety and efficacy is paramount. The 510(k) submission process is a critical step for manufacturers seeking clearance from the U.S. Food and Drug Administration (FDA) to market their devices. This process can be complex, but it plays a pivotal role in bringing innovative medical devices to

... Read moreNavigating French Language Labeling Requirements in Canada: A Guide for Food Manufacturers

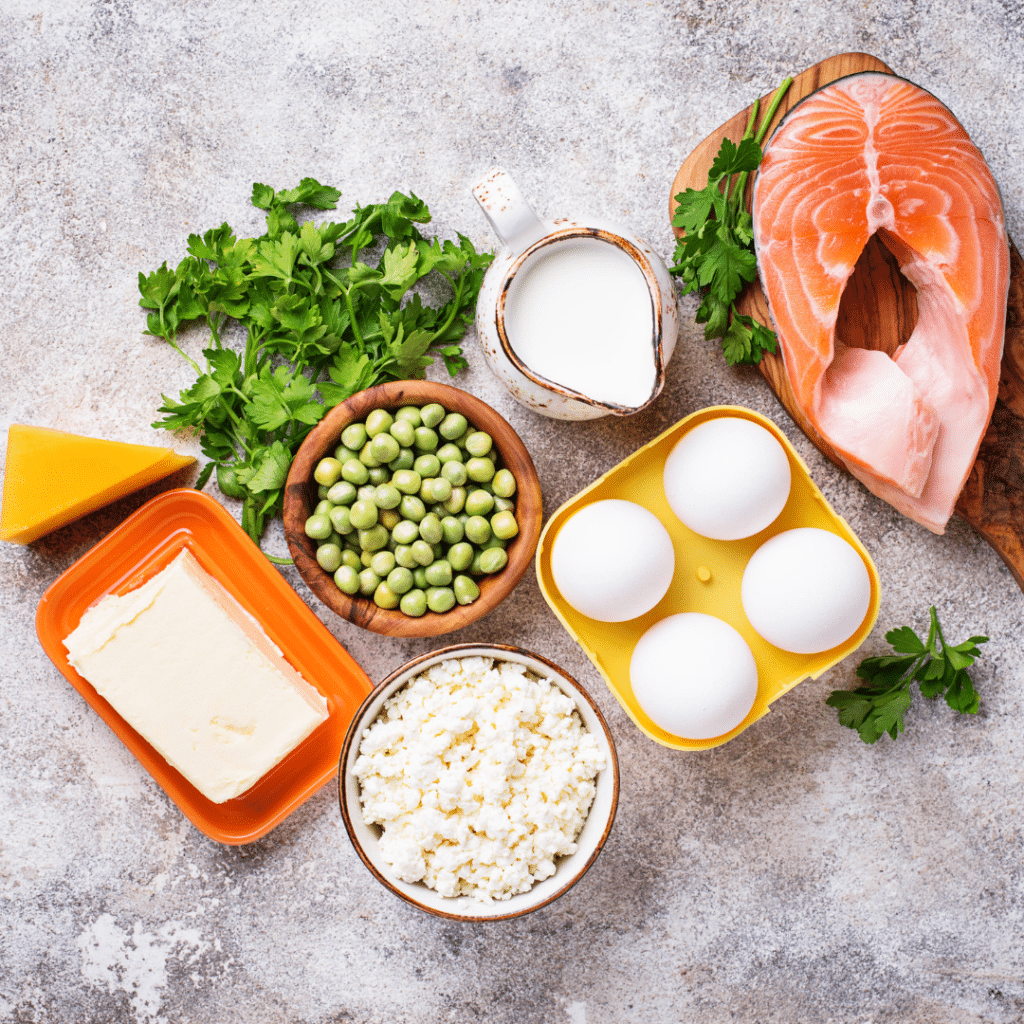

Introduction: As a food manufacturer in Canada, ensuring that your product labels comply with Health Canada’s regulations is crucial for successful market entry and consumer safety. For businesses looking to distribute food products in Canada, one essential aspect is adherence to bilingual labeling requirements, notably including French alongside English on product labels. In this blog,

... Read moreWhy is it crucial to avoid FDA Warning Letters for dietary supplements and health products?

As a business owner operating in dietary supplements and health products, you are undoubtedly aware of the ever-evolving regulatory landscape. Ensuring that your products meet the stringent requirements set forth by the U.S. Food and Drug Administration (FDA) is not merely a matter of legal obligation; it’s imperative for your brand’s success and consumer

... Read moreEverything businesses should know about submitting a 30-Day Pre-Market Notification and Structure-Function Claims

https://youtu.be/MlufAYFqQ1s In dietary supplements, navigating the intricate regulatory landscape is a challenging yet indispensable aspect of launching your product. Submitting a 30-day Pre-Market Notification and Structure-Function Claim to the U.S. Food and Drug Administration (FDA) is a pivotal regulatory requirement. This notification must be submitted at least 30 days before introducing your dietary supplement to

... Read moreHealth Canada’s Notice Enables the Use of L-alpha Glycerylphosphorylcholine in Supplemented Food

Health Canada Approves Alpha GPC in Foods On September 20, 2023, Health Canada approved the use of L-alpha-glycerylphosphorylcholine (alpha GPC) as a supplement in foods. This decision followed a thorough safety review by Health Canada’s Food Directorate. How Health Canada Administers Foods and Food Supplements Health Canada ensures food and drug safety is maintained in

... Read moreNavigating Cosmetic Product Regulations through FDA Recent MoCRA Update

https://youtu.be/uuXA8yHrrZc Introduction: In response to the FDA’s recent draft guidance on the Registration and Listing of Cosmetic Product Facilities and Products, we’ve got some updates and insights that might interest you, especially if you’re in the cosmetic business. First, nearly 50 public comments were submitted to the FDA regarding this draft guidance by the September 5,

... Read moreSelling Your Food Products in the USA: A Guide for Food Business Owners

https://youtu.be/x4c0LEPmJuM If you’re selling food products in the United States, understanding and complying with FDA regulations is non-negotiable. The Food and Drug Administration (FDA) has established rigorous requirements to ensure the safety and transparency of food products available to consumers. Here’s a practical guide tailored to food business owners on ensuring your food products meet

... Read moreHow to Obtain an NPN License for Your Natural Health Product in Canada

When it comes to selling natural health products (NHPs) in Canada, securing an NPN license is your ticket to success. Issued by Health Canada, this license confirms that your product is safe, effective, and manufactured to meet high-quality standards. It is not just about compliance; it is about building trust with your customers and standing

... Read moreHow to prepare and submit an eStar 510k Submission as of October 1st

Introduction: Staying up-to-date with the latest regulations and tools is crucial in medical device submissions. As of June 9, 2023, the FDA introduced the electronic Submission Template and Resource (eSTAR) for Pre-Submissions, revolutionizing the process for medical device applicants. Starting October 1, 2023, all 510(k) submissions, unless exempted, must be submitted electronically using the eSTAR template.

... Read more10 Steps to Sell Dietary Supplements in the U.S.

The dietary supplement industry in the U.S. is growing fast. More people are looking for vitamins, minerals, and other supplements to support their health. If you’re planning to sell supplements, you need to follow strict regulations to make sure your products are safe and legal. Unlike regular foods or prescription drugs, dietary supplements have their

... Read moreUnderstanding FSVP Rules and How to Stay Compliant

For importers in the global food trade, ensuring the safety and compliance of imported products is a top priority. The Foreign Supplier Verification Program (FSVP) is vital to this effort, requiring importers to adhere to specific rules and meticulously maintain accurate records. In this article, we’ll delve into everything importers need to know about FSVP

... Read moreWhat the Draft Guidance Means for MLMD Applications

*This summary of Health Canada’s guidance document provides compliance details for manufacturers submitting a new or amended application. Under the regulations, this applies to Class II, III, and IV for MLMD. It does not cover the non-ML information required in a medical device license application.* Artificial intelligence (AI) encompasses algorithms and models that perform tasks

... Read moreHow FSMA Strengthens Food Safety Compliance

The Food Safety Modernization Act (FSMA) Made Simple Imagine a world where preventing food-related illnesses is more important than dealing with them after they happen. That’s precisely what the FSMA, introduced in 2011, aims to achieve. The FSMA focuses on stopping contamination and illnesses before they occur, covering various stages of the food supply chain,

... Read moreFSVP Planning: Everything you should know before choosing an FSVP Agent for Import/Export

https://youtu.be/T3pLp1dF08Y Introduction: In the intricate world of global trade, ensuring the safety and compliance of imported and exported food products is a shared responsibility. The Foreign Supplier Verification Program (FSVP) stands as a cornerstone in this effort, safeguarding the well-being of consumers and the integrity of the food supply chain. When navigating the FSVP landscape,

... Read moreStaying Ahead of the Game: Key Insights on the Latest Requirements for New Drug Submissions

From FDA guidelines to global regulatory standards, understanding the nuances of each requirement is essential to ensure a timely and successful drug submission. Our experts have analyzed the latest updates and compiled a comprehensive guide to help you stay ahead of the curve. In the dynamic and highly regulated world of pharmaceuticals, staying ahead

... Read moreDemystifying GHP and GMP Regulatory Food Safety Audits: Why They Matter

In the realm of food production and processing, safety is paramount. Ensuring our food is free from contaminants and meets stringent quality standards is a shared responsibility. This is where Good Hygiene Practices (GHP) and Good Manufacturing Practices (GMP) come into play. This comprehensive guide will explore the significance of GHP and GMP regulatory food

... Read more